The Dollfus & Muller sanforizing felts are used on the Palmer unit of the compressive shrinking range or sanforizing machine.

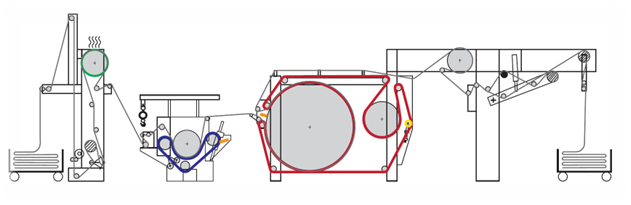

The sanforizing machine does for plain woven fabric what a compactor does for knitted fabrics : Pre-shrinking and stabilization. The difference comes from the fact that the shrinkage is not given by the felt, but by a thick rubber belt using steam and mechanical pressure on the first unit of the machine. Sanforizing machines are used in shirting, bottom-weight and Denim finishing plants.

The sanfor felt also called Palmer felt, shrinking felt, zero zero felt blanket, drying felt or Sanfor blanket has mainly two purposes:

- To dry the wet fabric coming from the shrinking unit,

- To improve the fabric handle.

Dollfus & Muller felts offer the best drying, an excellent shrinkage control and a very good hand to the fabric.

Dollfus & Muller has developed special reinforced Denim Sanfor felts in order to resist longer to the chemicals used in Denim processing.

Compatible machine brands

Choices | Description | Reference | Characteristics | ||||

|---|---|---|---|---|---|---|---|

Composition | Max. working T° | Thickness (mm) | Weight (g/m²) | Air permeability (CFM: Cubic Feet / min under 124 Pa) | |||

Standard Palmer felts | Original quality | SYPOR 200 | 100% Polyester | 160°C / 320°F | 6 | 2000 | 10 |

Stronger quality | SYPOR 240 | 100% Polyester | 160°C / 320°F | 7 | 2400 | 8 | |

Reinforced Palmer felts | Recommended for Denim finishing | SYPOR 243 TN | 100% Aramid | 190°C / 370°F | 7 | 2400 | 11 |

Other felts from the Palmer unit | Recommended for the finishing of some sensitive fabrics | SYPOR SLS 200 | 50% Wool / 50% Polyester | 160°C / 320°F | 6 | 2000 | 11 |