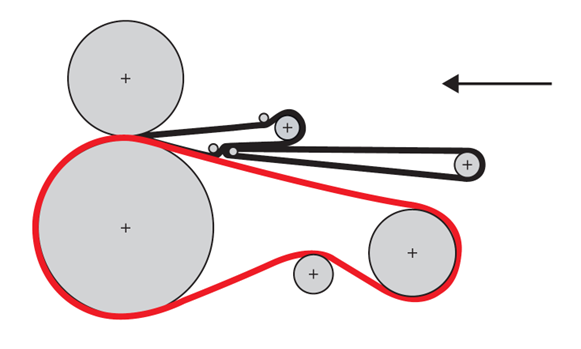

During the ironing and embossing through feed process, the hide is conveyed on the felt and then goes through the cylinder under high pressure in order to provide the final look and touch to the skin.

A complete range of felts adapted to the different kinds of processes, from ironing to deep embossing, for soft / thin leather to heavy ones, are available. Dollfus & Muller ironing and embossing felts are designed to avoid any risk of folds or non homogeneous embossing. The soft surface is the result of a specific treatment which allows a constant thickness and hardness overall the surface. Anti static fibres are used to avoid static electricity problems, specially during winter time for ironing processes.

Dollfus & Muller is manufacturing very soft ironing felts to iron leather. These ironing felts are either mixed felts or 100% woollen felts for very sensitive leather. Furthermore, Dollfus & Muller is manufacturing high pressure felts for deep embossing and heavy duty embossing machines.

Compatible machine brands

Production | Process | Type of leather | Working parameters | Reference | Characteristics | |||||

|---|---|---|---|---|---|---|---|---|---|---|

Pressure (bar) | Max. working T° | Composition | Weight (g/m²) | Thickness (mm) | Density | |||||

Automotive, upholstery | Heavy embossing | Heavy and thick leather Ex: Cow, Buffalo | up to 230 | <160°C | EMBO M 91 | 50% wool - 50% synthetic + anti-static fibers | 9100 | 13.5 | 670 | |

Medium to heavy embossing | Heavy and thick leather Ex: Cow, Buffalo | up to 200 | <160°C | EMBO M 81 | 50% wool - 50% synthetic + anti-static fibers | 8100 | 12.5 | 640 | ||

Ironing and medium embossing | Thin leather Ex: Cow, Pig, Calf | up to 120 | <160°C | EMBO M 70 | 50% wool - 50% synthetic + anti-static fibers | 7000 | 11.5 | 610 | ||

Footwear, luggage, clothing | Ironing and medium embossing | Sensitive leather Ex: Goat, Sheep | up to 120 | <120°C | EMBO W 60 | 100% wool | 6000 | 10.5 | 570 | |