Tannery felts

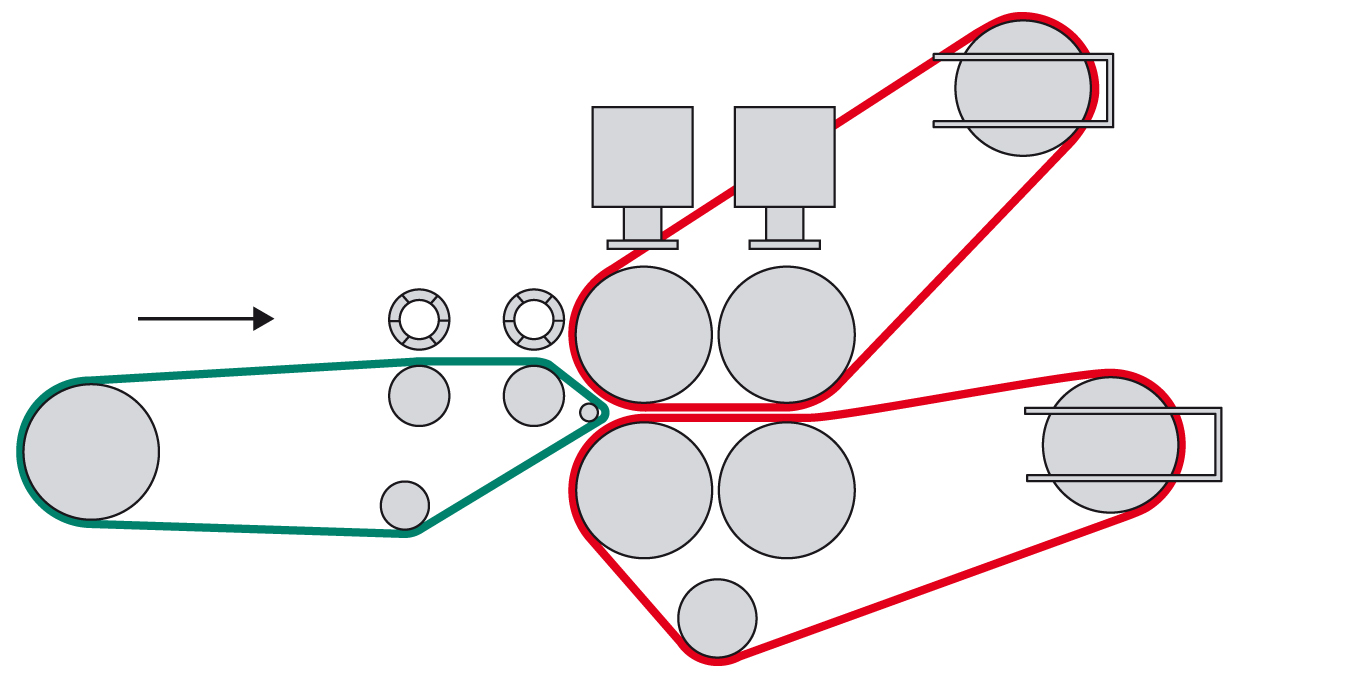

During this process, the skin is conveyed through cylinders equipped with blades, which stretch and soften it. The hide is then passed between two felts to drain off excess water.

Continuous winders are always equipped with 4 compressor-cylinders.

Dollfus & Muller manufactures felts for MVC4 , PRC4 and PCR 4 spinners.

Dollfus & Muller windrower felts have a special surface treatment that optimizes skin stretch.

Technical documents

Document

Compatible machine brands

Bauce

CM

Escomar

Type of skin | Production | Process | Machine type | Reference | Characteristics | |||

|---|---|---|---|---|---|---|---|---|

Composition | Weight (g/m²) | Thickness (mm) | Water permeability l/h/10cm² (under 2 bars of water pressure) | |||||

All types | Automotive, Upholstery, Shoes, Gloves, Bags, Garments | After dyeing | 5 pressure cylinders | SETO S 95 | 100% synthetic | 9500 | 18 | 350 |

SETO S 85 | 8500 | 17 | 300 | |||||